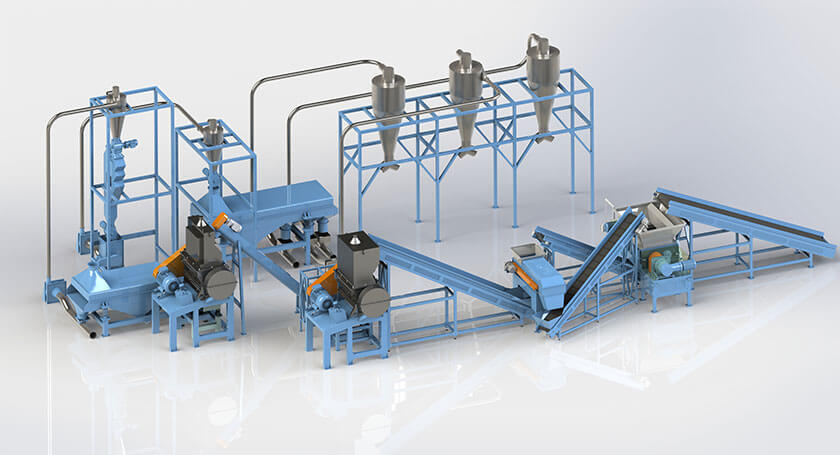

The rubber powder plant is designed to convert whole scrap tires into high quality, uncontaminated rubber powder. This plant can produce rubber powder from 500kgs to 5 tons an hour in capacity and the powder size can be as fine as 120mesh adjusted by centrifugal screen.

Rubber Powder is the final result of ambient tire recycling. At this stage, crumb rubber is ground down into a clean powder form with virtually all steel and fiber removed. Rubber Powder has numerous secondary uses from injection molding products, coatings, roofing materials and various asphalt applications.

★ LIKE Tire Recyling collection and processing facilities convert automobile,truck,off-road tires even OTR tires into innovative and useful products.

The rubber crumb plant is proven to convert whole scrap tires into high quality, uncontaminated crumb rubber. This plant is designed to process from 300kgs to 4 tons an hour in capacity and process 1-6mm crumb rubber.

Rubber Powder is typically found in 400 – 74 microns (0.400 – .074 mm) in size. This micron-size material has the advantage of being incorporated into new or existing formulations for various polymers and finished products.