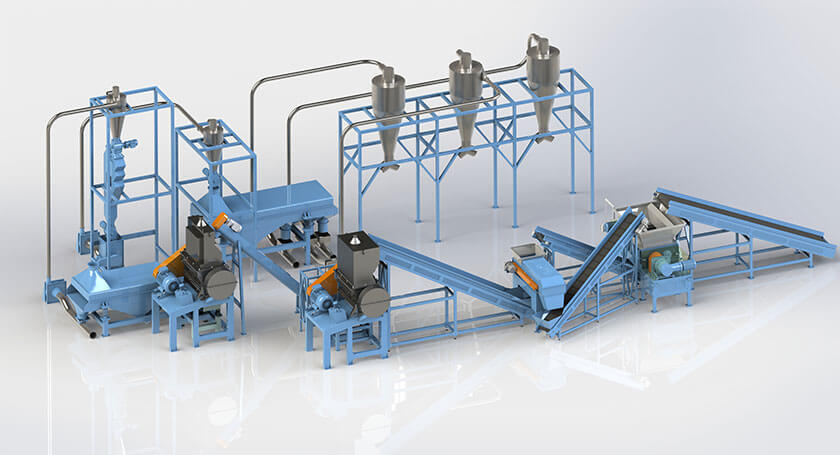

LIKE tire shredding system is designed to produce up to 6 tons per hour of wire free rubber mulch. This system produces up to a 99% wire free chip ranging in size between 12-25mm (0.47’’and 1.0’’) depending on the desired size. After processing, the steel is removed by our magnetic separation system.

Wire-free Chips or Rubber Mulch are shreds that exit through the second station or secondary shredder of a tire recycling line. At this stage, rough shreds from the primary shredder are processed into a uniform chip with steel removed through a wire cleaning/magnet removal process. These chips are typically 99.9% wire-free. Wire-free chips are typically found in 1 ¼” – 3/8” inch in size.

Wire-free chips have numerous uses from landscaping and playgrounds to engineering applications. An added value of wire-free chips is the ability to remove the steel and sell to buyers. Wire-free mulch is a low-maintenance material for landscapers and homeowners.

The rubber crumb plant is proven to convert whole scrap tires into high quality, uncontaminated crumb rubber. This plant is designed to process from 300kgs to 4 tons an hour in capacity and process 1-6mm crumb rubber.

The rubber powder plant is designed to convert whole scrap tires into high quality, uncontaminated rubber powder. This plant can produce rubber powder from 500kgs to 5 tons an hour in capacity and the powder size can be as fine as 120mesh adjusted by centrifugal screen.

The advantages of rubber mulch made by LIKE Tire recycling system.

• 100% Recycled Rubber

• 99.9% Wire Free

As One of the leading manufacturers of tire recycling system, LIKE can offer the quality machines to make quality rubber mulch, rubber infill and rubber topdressing products into the residential, commercial, sports, equestrian and military markets.